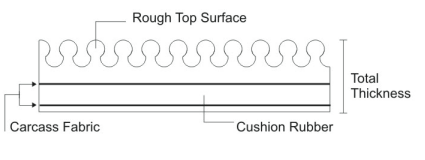

Our Rough Top Conveyor Belt is specifically designed for the smooth and efficient transportation of lightweight and fragile goods, whether on inclines or flat surfaces. The belt’s textured surface ensures a secure grip, making it ideal for handling delicate or deformable materials such as glass, paper, bags, boxes, and cartons. With the ability to transport items at angles between 15 to 35 degrees, Neelkanth Rubber Mills’ Rough Top belts are the perfect solution for industries requiring gentle yet reliable material handling.

Industries

Packaging

Warehousing

Airport

1. Superior grip and friction for secure transportation.

2. Prevents material slippage on inclined and flat surfaces.

3. Reduces damage to fragile items like glass, paper, bags, and cartons.

4. Durable and long-lasting even in continuous operation.

Rough Top Conveyor Belts are widely used in industries such as:

1. Packaging – Smooth transport of cartons, boxes, and fragile materials.

2. Warehousing & Logistics – Efficient handling of goods in distribution centers.

3. Airports – Safe and reliable luggage transportation on conveyor systems.

1. Regular cleaning to remove dust and debris for consistent grip.

2. Inspect belt tension to prevent slippage and maintain efficiency.

3. Check for surface wear to ensure extended operational life.

You can send an enquiry through our website by clicking the "Send Enquiry" button or by directly contacting our sales team at sales@neelkanthrubbermills.com

Copyright ©2025 Neelkanth Rubber Mills. All Rights Reserved | Designed by Hellotechindia