Neelkanth provides premium rubber conveyor belts in multiple cover grades and duty applications, suited for industries like power plants, mining, steel and other industrial applications. Designed for efficient and reliable material handling, our belts ensure durability and performance under demanding conditions. With a focus on quality and innovation, Neelkanth’s conveyor solutions meet the rigorous needs of modern industries, enhancing operational efficiency and productivity across diverse applications.

| Width | up to 2500 mm |

|---|---|

| Length | Open or endless |

| Plies | 3 to 7 plies |

| Thickness | up to 40 mm |

| Tensile Strength | up to 2500 KN/M |

| Types of Synthetic Carcass | General Duty (GD), Extra Duty (ED) & Heavy Duty (HD) |

| Edges | Cut edge or Moulded edge |

| Breaker Ply | Breaker is provided on the face, back & edges as per requirement |

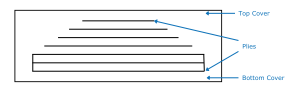

| Ply Construction | Straight Ply, Stepped Ply & Reversed Stepped Ply |

| Fabric | Cotton/Cotton, Cotton/Nylon & Synthetic Fabric like Nylon/Nylon and Polyester/Nylon (EP) |

Neelkanth’s General Purpose and Heavy-Duty conveyor belts are designed to perform under demanding conditions, handling abrasive materials with exceptional efficiency. Engineered for superior resistance to cutting and tearing, these belts ensure durability and reliable performance over extended periods. Their robust construction minimizes maintenance needs while adhering to the highest quality standards.

Steel

Mining

Power Plants

Ports

Cement

Aggregates

Lumber

Agriculture

Steel

Mining

Power Plants

Ports

Cement

Aggregates

Lumber

Agriculture

Our heat-resistant conveyor belts are specifically engineered to handle materials exposed to elevated temperatures, ensuring durability and reliability in high-temperature environments. Available in multiple grades to meet varying industrial requirements

Manufactured to adhere to both domestic and international standards, these belts provide a safe and dependable solution for industries requiring high-temperature performance.

Steel

Power Plants

Foundries

Neelkanth’s oil-resistant conveyor belts are expertly designed to handle oily and greasy materials without compromising performance or durability. Engineered to prevent material degradation and extend belt life, they ensure smooth operations even in challenging environments. With excellent resistance to oil penetration and superior tensile strength, these belts deliver consistent performance while minimizing wear and maintenance needs.

Petro-Chemical

Oil & Gas

Lumber

Recycling

Neelkanth’s fire-retardant conveyor belts are specifically designed for high-risk environments where safety is paramount. These self-extinguishable belts provide essential protection against fire hazards, ensuring reliable performance in fire-prone conditions. Engineered to deliver exceptional durability and compliance with stringent safety standards, they offer a secure solution for critical applications.

Steel

Mining

Foundries

Power Plants

Petro-chemical

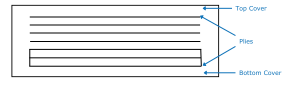

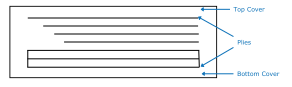

A conveyor belt is a continuous moving system designed to transport materials efficiently across industries like mining, steel, power plants, cement, agriculture, and logistics.

We manufacture conveyor belts in many cover grades for various industrial applications, including:

1. General Purpose & Heavy-Duty Conveyor Belts

2. Heat-Resistant Conveyor Belts

3. Oil-Resistant Conveyor Belts

4. Fire-Retardant Conveyor Belts

Our conveyor belts are used in mining, steel, cement, power plants, ports, foundries, petrochemical industries, recycling, lumber, and agriculture

Our conveyor belts are designed for high performance, durability, and resistance to impact, heat, fire, and oil, ensuring long-term reliability in demanding conditions.

We offer three main constructions:

Straight Ply – Ensures consistent tensile strength and load distribution.

Stepped Ply – Provides enhanced flexibility and edge wear resistance.

Reversed Stepped Ply – Offers superior edge protection and even stress distribution for heavy-duty applications.

Our belts come with Cut Edge or Moulded Edge, depending on industrial needs.

Yes, our conveyor belts can be customized in terms of width, thickness, ply construction, edge type, and special coatings to suit your industry.

Our conveyor belts are designed with:

High-performance adhesion for durability

Impact-resistant cushioning to absorb heavy loads

Superior moisture shielding to prevent water damage

Enhanced flex-trough design for better material handling efficiency

We provide belt fasteners, pulley lagging, idlers, skirting, and other essential accessories.

You can contact us through our website or email us at sales@neelkanthrubbermills.com or call our sales team at +91-6284841342 for a personalized quote.

Copyright ©2025 Neelkanth Rubber Mills. All Rights Reserved | Designed by Hellotechindia