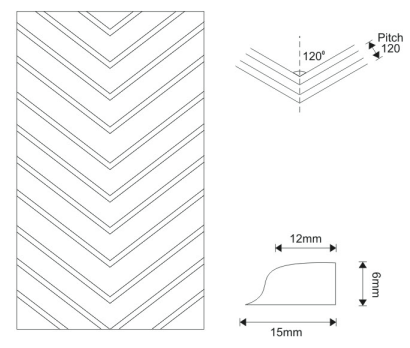

At Neelkanth Rubber Mills, our Chevron Conveyor Belts are engineered for optimal performance on steep inclines, offering a distinctive V-shaped cleat pattern that provides excellent grip. Designed to prevent material slippage during transportation, these belts are perfect for handling bulk materials like coal, sand, and minerals on inclines of up to 40 degrees. Whether used in construction, mining, or agriculture, our Chevron belts ensure efficient material transport with minimal spillage. Trust Neelkanth Rubber Mills to deliver high-quality, durable solutions for your most demanding conveyor applications.

Industries

Mining

Stone Crushers

Cement

Agriculture

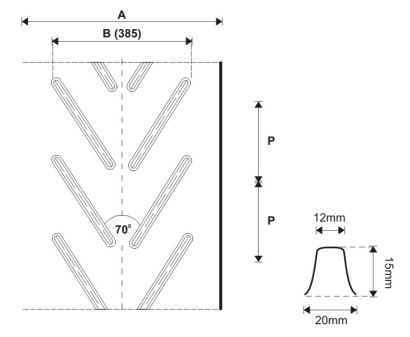

| A | B | P | |

|---|---|---|---|

| (B.W.) | (C.W.) | (C.P.) | (C.H.) |

| 450 | 385 | 250 | 15 |

| 500 | 385 | 250 | 15 |

| 600 | 385 | 250 | 15 |

| 650 | 385 | 250 | 15 |

| 700 | 385 | 250 | 15 |

| 750 | 700 | 330 | 15 |

| 800 | 700 | 330 | 15 |

| 900 | 700 | 330 | 15 |

| 1000 | 700 | 330 | 15 |

| 1200 | 700 | 330 | 15 |

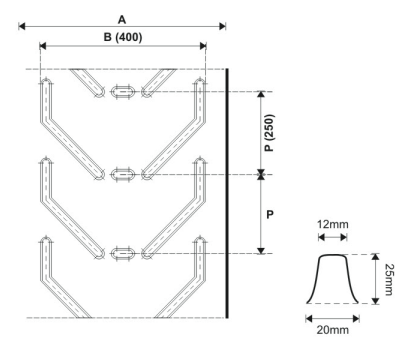

| A | B | P | |

|---|---|---|---|

| (B.W.) | (C.W.) | (C.P.) | (C.H.) |

| 450 | 400 | 250 | 25 |

| 500 | 400 | 250 | 25 |

| 600 | 400 | 250 | 25 |

| 650 | 400 | 250 | 25 |

| 700 | 400 | 250 | 25 |

| 750 | 700 | 330 | 25 |

| 800 | 700 | 330 | 25 |

| 850 | 700 | 330 | 25 |

| 900 | 700 | 330 | 25 |

| 1000 | 700 | 330 | 25 |

| 1200 | 700 | 330 | 25 |

| B. W. | C. W. | C. P. | C. H. |

|---|---|---|---|

| 450 | 450 | 100 | 6 |

| 500 | 500 | 100 | 6 |

| 600 | 600 | 100 | 6 |

| 650 | 650 | 100 | 6 |

| 700 | 700 | 100 | 6 |

These heights provide the necessary grip and support for different material types.

Yes, we offer custom widths, cleat heights, and rubber compounds to meet specific industrial needs. Contact our team for tailored solutions.

You can send an enquiry through our website by clicking the "Send Enquiry" button or by directly contacting our sales team at sales@neelkanthrubbermills.com

Copyright ©2025 Neelkanth Rubber Mills. All Rights Reserved | Designed by Hellotechindia